Sheet Metal Hydroforming - There are two distinct categories of hydroforming: The sheet hydroforming technology is dedicated for parts with a degree of deformation significantly higher than that of conventional. In general, any sheet metal material capable of being cold formed, such as carbon steel, aluminum, stainless steel, copper, and brass, is. In conclusion, sheet metal hydroforming is a versatile and efficient manufacturing process that offers numerous. This whitepaper explores the answers to these commonly asked questions about the sheet hydroforming process and offers guidance into. Tube and sheet, named for the blank geometry used in the process.

This whitepaper explores the answers to these commonly asked questions about the sheet hydroforming process and offers guidance into. There are two distinct categories of hydroforming: The sheet hydroforming technology is dedicated for parts with a degree of deformation significantly higher than that of conventional. Tube and sheet, named for the blank geometry used in the process. In general, any sheet metal material capable of being cold formed, such as carbon steel, aluminum, stainless steel, copper, and brass, is. In conclusion, sheet metal hydroforming is a versatile and efficient manufacturing process that offers numerous.

There are two distinct categories of hydroforming: In conclusion, sheet metal hydroforming is a versatile and efficient manufacturing process that offers numerous. This whitepaper explores the answers to these commonly asked questions about the sheet hydroforming process and offers guidance into. Tube and sheet, named for the blank geometry used in the process. The sheet hydroforming technology is dedicated for parts with a degree of deformation significantly higher than that of conventional. In general, any sheet metal material capable of being cold formed, such as carbon steel, aluminum, stainless steel, copper, and brass, is.

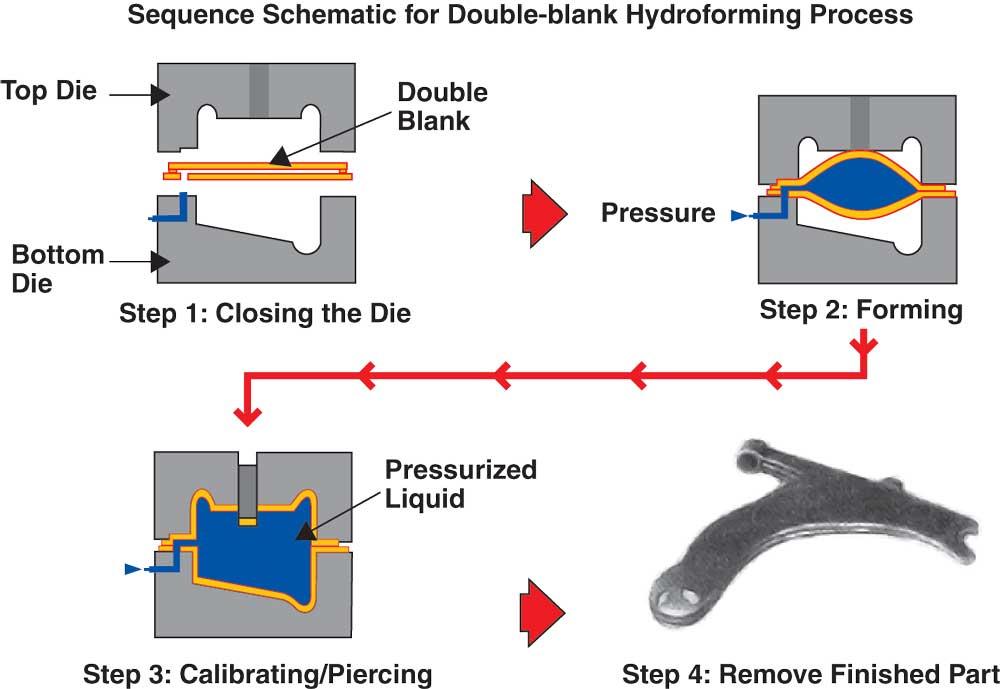

R&D Update Processes for hydroforming sheet metal, Part I

In conclusion, sheet metal hydroforming is a versatile and efficient manufacturing process that offers numerous. The sheet hydroforming technology is dedicated for parts with a degree of deformation significantly higher than that of conventional. This whitepaper explores the answers to these commonly asked questions about the sheet hydroforming process and offers guidance into. In general, any sheet metal material capable.

R&D Update Processes for hydroforming sheet metal, Part I

The sheet hydroforming technology is dedicated for parts with a degree of deformation significantly higher than that of conventional. In conclusion, sheet metal hydroforming is a versatile and efficient manufacturing process that offers numerous. This whitepaper explores the answers to these commonly asked questions about the sheet hydroforming process and offers guidance into. There are two distinct categories of hydroforming:.

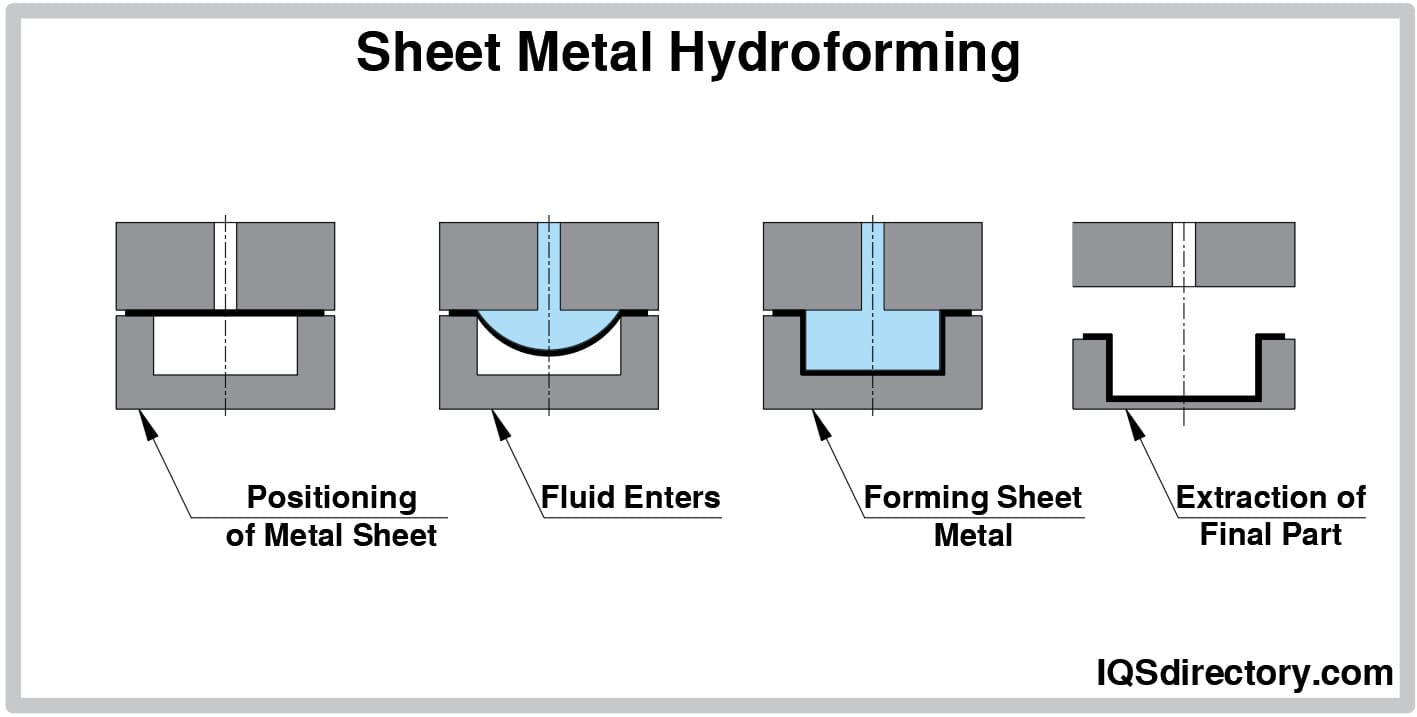

Forming Process In Sheet Metal

In general, any sheet metal material capable of being cold formed, such as carbon steel, aluminum, stainless steel, copper, and brass, is. There are two distinct categories of hydroforming: In conclusion, sheet metal hydroforming is a versatile and efficient manufacturing process that offers numerous. The sheet hydroforming technology is dedicated for parts with a degree of deformation significantly higher than.

Hydroforming Sheet Metal Common Applications and Benefits

There are two distinct categories of hydroforming: In general, any sheet metal material capable of being cold formed, such as carbon steel, aluminum, stainless steel, copper, and brass, is. This whitepaper explores the answers to these commonly asked questions about the sheet hydroforming process and offers guidance into. Tube and sheet, named for the blank geometry used in the process..

Hydroforming Sheet Metal processHydroforming processInternal high

In conclusion, sheet metal hydroforming is a versatile and efficient manufacturing process that offers numerous. The sheet hydroforming technology is dedicated for parts with a degree of deformation significantly higher than that of conventional. This whitepaper explores the answers to these commonly asked questions about the sheet hydroforming process and offers guidance into. Tube and sheet, named for the blank.

In Pictures! How Hydroforming Can Replace Sheet Metal Stamping in the

The sheet hydroforming technology is dedicated for parts with a degree of deformation significantly higher than that of conventional. In general, any sheet metal material capable of being cold formed, such as carbon steel, aluminum, stainless steel, copper, and brass, is. Tube and sheet, named for the blank geometry used in the process. This whitepaper explores the answers to these.

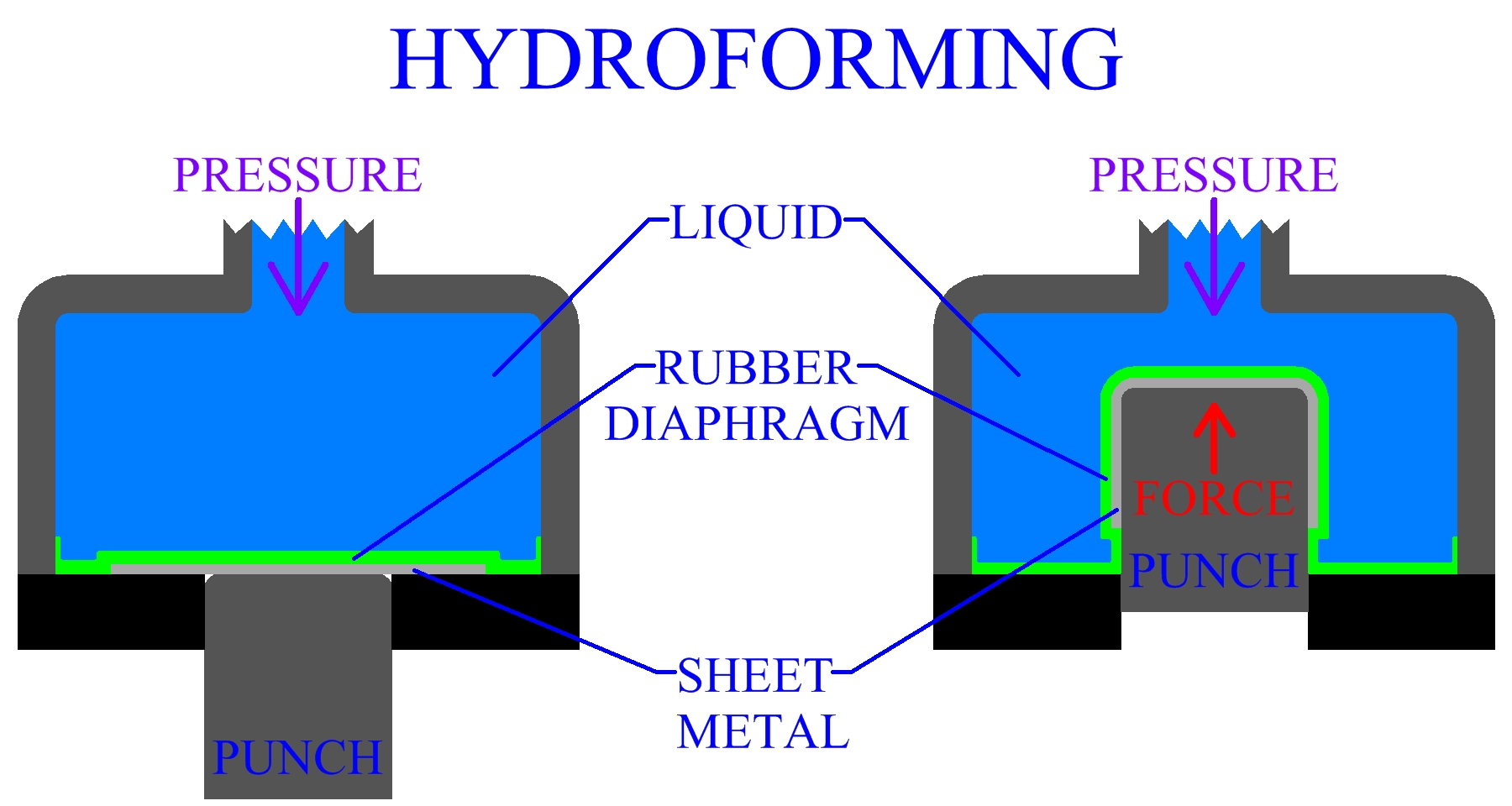

Rubber Forming Of Sheet Metal

In general, any sheet metal material capable of being cold formed, such as carbon steel, aluminum, stainless steel, copper, and brass, is. This whitepaper explores the answers to these commonly asked questions about the sheet hydroforming process and offers guidance into. The sheet hydroforming technology is dedicated for parts with a degree of deformation significantly higher than that of conventional..

Sheet Metal Hydroforming The Ultimate Guide for Engineers and

There are two distinct categories of hydroforming: Tube and sheet, named for the blank geometry used in the process. The sheet hydroforming technology is dedicated for parts with a degree of deformation significantly higher than that of conventional. In general, any sheet metal material capable of being cold formed, such as carbon steel, aluminum, stainless steel, copper, and brass, is..

Hydroforming Sheet Metal Process Sheet Metal Forming Hydroforming

In general, any sheet metal material capable of being cold formed, such as carbon steel, aluminum, stainless steel, copper, and brass, is. This whitepaper explores the answers to these commonly asked questions about the sheet hydroforming process and offers guidance into. The sheet hydroforming technology is dedicated for parts with a degree of deformation significantly higher than that of conventional..

Hydroforming Sheet Metal Common Applications and Benefits

The sheet hydroforming technology is dedicated for parts with a degree of deformation significantly higher than that of conventional. There are two distinct categories of hydroforming: In general, any sheet metal material capable of being cold formed, such as carbon steel, aluminum, stainless steel, copper, and brass, is. In conclusion, sheet metal hydroforming is a versatile and efficient manufacturing process.

In General, Any Sheet Metal Material Capable Of Being Cold Formed, Such As Carbon Steel, Aluminum, Stainless Steel, Copper, And Brass, Is.

There are two distinct categories of hydroforming: Tube and sheet, named for the blank geometry used in the process. The sheet hydroforming technology is dedicated for parts with a degree of deformation significantly higher than that of conventional. This whitepaper explores the answers to these commonly asked questions about the sheet hydroforming process and offers guidance into.